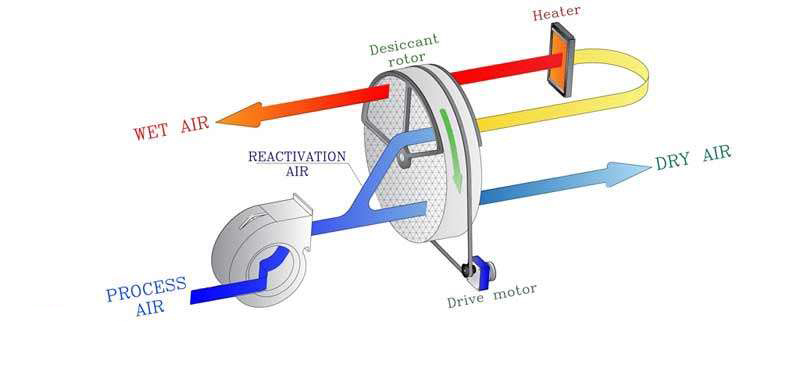

Mode of Operation 1: Compact & Efficient Dehumidification

This mode is used in MDC250, our smallest desiccant dehumidifier, where a single radial fan manages both process air and reactivation airflows. This setup simplifies installation while maximising heat recovery, achieving the lowest possible dew point.

How It Works:

Process Airflow: Humid air passes through the silica gel desiccant wheel, which absorbs moisture efficiently. The dried air is then supplied to the intended space.

Reactivation Airflow: A portion of the rotor first pre-dries and preheats the reactivation air. This air is then heated to 90-140°C and directed through the regeneration zone, evaporating the absorbed moisture. The warm, humid air is then exhausted outside.

Continuous Process: The rotor continuously absorbs and regenerates, ensuring a steady supply of dry air. A sealed holding frame prevents air mixing, while the absence of condensation means no drainage connection is required.

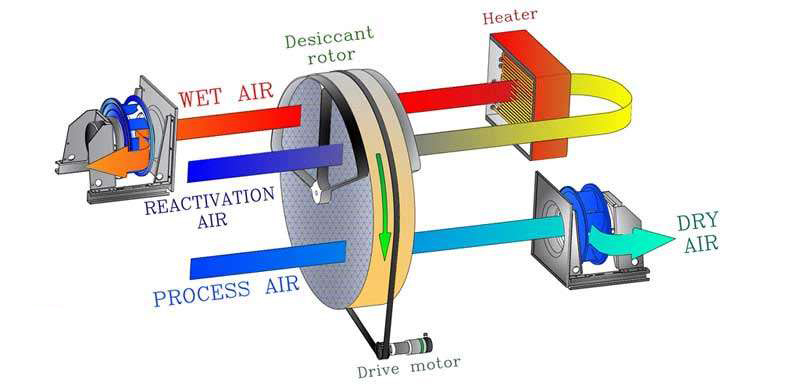

Mode of Operation 2: High-Performance Air Drying

This is the most commonly used system, implemented in desiccant dehumidifiers ranging from MDC450 to MDC3000. It is designed for ultra-low humidity levels, achieving near 0% RH.

How It Works:

Dual Fan System: Separate centrifugal fans handle process air and reactivation airflows for enhanced efficiency.

Process Airflow: Humid air moves through the silica gel rotor, which extracts moisture across ~75% of the rotor face before supplying dry air to the space.

Reactivation Airflow: The air is heated to 90-140°C, allowing the rotor to release moisture into the outgoing airflow, which is then expelled outside.

Nonstop Operation: The rotor continuously rotates, providing an uninterrupted adsorption and reactivation process. A sealed frame prevents air leakage, and no drainage system is required.

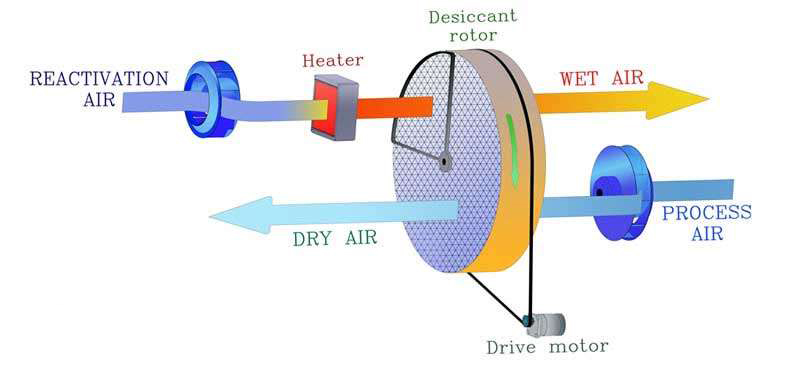

Mode of Operation 3: Energy-Efficient Heat Recovery

This mode, used in MDC4000 and larger models, incorporates heat recovery technology, reducing power consumption and minimising temperature increases in the dry air supply.

How It Works:

Optimised Heat Recovery: During reactivation, the rotor absorbs and retains heat, preheating and partially dehumidifying the incoming reactivation air before it reaches the heater.

Dual Fan System: Two centrifugal fans manage separate process and reactivation airflows.

Process Airflow: Moist air passes through the silica gel rotor, extracting water molecules across ~60% of the rotor surface before being supplied as dry air.

Reactivation Airflow: The air first passes through a purge zone, recovering heat from the rotor, before being heated to 90-140°C for full regeneration. Moist air is then expelled outside.

Continuous Operation: The sealed rotor system prevents cross-contamination between process and reactivation air, ensuring reliable dehumidification without requiring a drainage connection.