Quick Scrolls

Low Dew Point Dehumidifiers for Li-Ion Battery Production & Dry Rooms

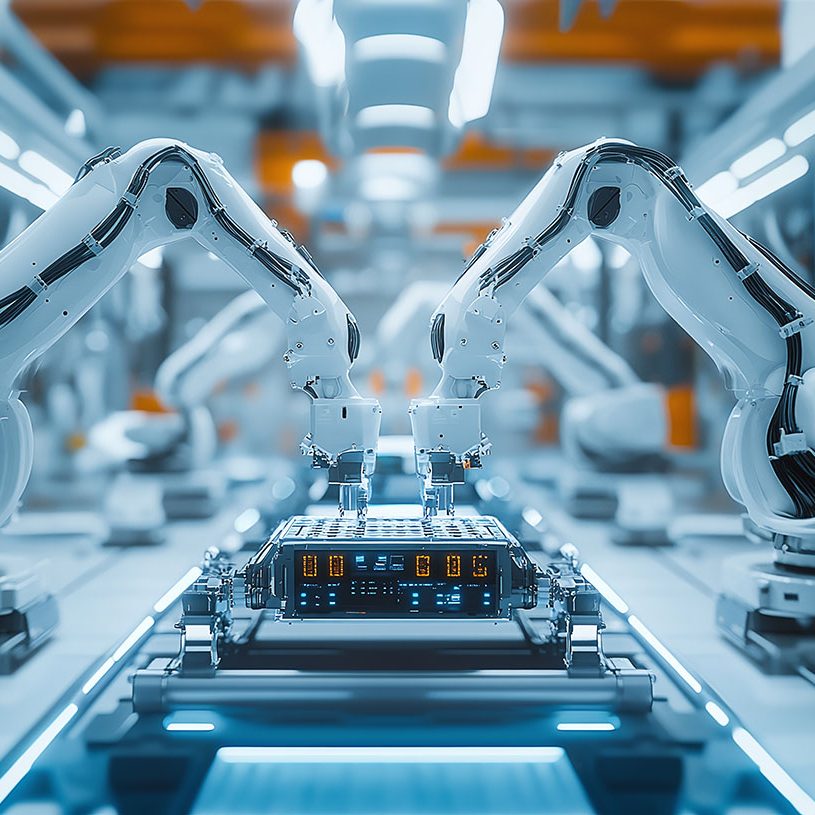

The demand for Lithium-ion (Li-ion) batteries is rapidly growing as industries shift towards electrification, renewable energy storage, and sustainability. To ensure high-quality battery production, dry rooms with precise humidity control are essential. Uncontrolled moisture can compromise battery performance, leading to reduced efficiency, safety risks, and production inefficiencies.

Why Dry Rooms are Essential for Li-Ion Battery Production

Li-ion battery manufacturing requires controlled ultra-dry environments to prevent:

- Moisture contamination in electrolyte filling – leading to chemical instability

- Reduced battery performance and lifespan – caused by humidity-induced defects

- Safety risks, such as thermal runaway – due to moisture reacting with battery components

- Corrosion of sensitive battery materials – affecting conductivity and efficiency

- Quality inconsistencies in production – leading to increased waste and rework costs

To ensure maximum product quality and safety, humidity levels must be kept as low as possible, especially at critical production stages.

What is a ‘Dry Room’?

A dry room is a specialised manufacturing environment with precisely controlled low humidity levels, classified by its dew point temperature (Tdp):

- Standard Dry Rooms: Dew point from -35°C to -65°C

- Advanced Dry Rooms: Dew point below -75°C for next-generation battery production

Maintaining these ultra-low humidity levels is critical during electrolyte filling, assembly, and sealing processes to prevent moisture-related defects.

DT Group’s Energy-Efficient Dry Room Solutions

Dry room climate control systems must be designed to:

- Minimise energy consumption – as dry room operation is one of the biggest cost factors in battery production

- Ensure airtight room construction – to reduce moisture infiltration

- React quickly to external humidity fluctuations – maintaining stable production conditions

With these goals in mind, Desiccant Technologies Group focuses on dual-rotor desiccant dehumidifier systems to deliver a continuous supply of ultra-dry air, setting a new benchmark for battery production environments.

Key Features of Our Dry Room Dehumidification Systems

Each battery production project is unique, and our systems are customised to meet specific dry room requirements. Some key features include:

- Full stainless steel construction (AISI316) – ensuring hygienic, corrosion-resistant operation

- Zinc-free materials – eliminating contamination risks

- Heat recovery systems – improving energy efficiency and reducing operational costs

- Adaptability to large volumes of fresh air intake – to support process exhaust requirements

- Single or dual-rotor desiccant dehumidification systems – delivering unmatched ultra-low dew point control

Customised Dry Room Solutions for Battery Production

At Desiccant Technologies Group, we work closely with manufacturers to develop energy-efficient, reliable, and scalable dehumidification systems that meet the stringent requirements of Li-ion battery production.

- Optimised for ultra-low dew points

- Designed to reduce energy consumption

- Ensuring long-term performance and reliability

Whether you are building a new dry room or upgrading an existing facility, our team provides tailored solutions to achieve the required microclimate for optimal battery production.