Quick Scrolls

Frozen Food Industry: Solving Humidity Challenges

Maintaining optimal humidity levels is crucial for freezing, storing, and processing frozen food. Uncontrolled moisture can lead to ice buildup, condensation, equipment malfunctions, and product deterioration. Desiccant dehumidifiers provide a highly efficient solution by removing excess moisture from the air, ensuring hygienic, energy-efficient, and long-lasting storage conditions.

The Impact of Uncontrolled Humidity in Frozen Food Storage

Excess moisture in freezing environments can cause:

- Condensation on cold surfaces – leading to ice buildup on equipment

- Frequent freezer defrosting – increasing maintenance time and costs

- Ice formation on products – affecting quality and safety

- Moisture buildup on evaporators – reducing cooling efficiency

- Metal corrosion – damaging equipment and structures

- Mould and bacteria growth – compromising food hygiene

- Deterioration of packaging materials – leading to waste and spoilage

- Failures in electronic and electrical systems – causing unexpected downtime

Why Choose Desiccant Dehumidifiers for Frozen Food Processing?

Desiccant dehumidifiers from Desiccant Technologies Group are engineered for efficiency and reliability in cold storage environments. Our systems offer:

- High drying efficiency with low energy consumption

- Effective operation in low temperatures

- Compact, lightweight design for easy installation

- Fully automated humidity control for seamless operation

- Corrosion-resistant casing (stainless steel or Aluzinc) for durability

- Compliance with all EU Directives and quality standards

By integrating our desiccant rotor technology, we maintain optimal humidity and airflow conditions throughout frozen food production and storage.

Optimising Freezer Humidity Control

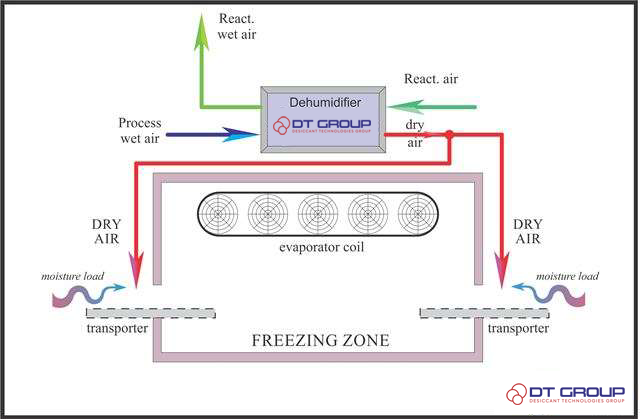

Freezers Without an Airlock Chamber

Many tunnel or spiral conveyor freezers lack airlock chambers, allowing moisture to enter freely. To reduce humidity, it is essential to control airflow at entry and exit points of the freezing zone.

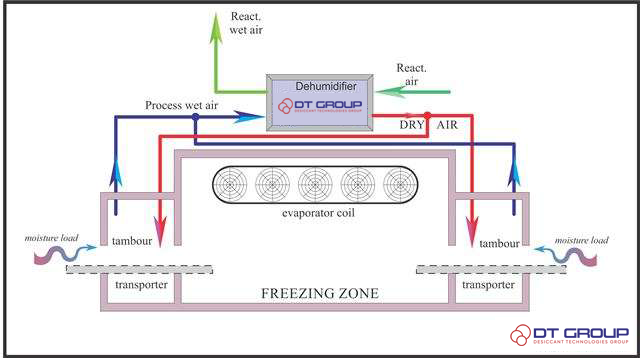

Freezers With an Airlock Chamber

Humidity control is more efficient when freezers are equipped with an airlock chamber. In this setup, air is dried before entering the freezer, preventing moisture buildup and ice formation.

Benefits of Installing DT Group Dehumidifiers

Our high-tech desiccant dehumidifiers create an ideal microclimate for frozen food production and storage by:

- Preventing condensation, ice buildup, and mould growth

- Protecting equipment from corrosion and extending its lifespan

- Reducing defrosting frequency and energy consumption

- Maintaining product quality and packaging integrity

- Improving hygiene conditions in storage and production areas

- Enhancing the durability of structural components

With decades of expertise, Desiccant Technologies Group delivers the most advanced dehumidification solutions for the frozen food industry, ensuring reliable, efficient, and compliant humidity control.