Ultra-Low Humidity Control for Li-Ion Battery Prototype Laboratory

Project: MDC DRYROOM

Quick Scrolls

The Challenge

Achieving Near-Zero Humidity in a Controlled Laboratory Environment

Lithium-ion battery (Li-ion) manufacturing requires strict humidity control, as even minimal moisture exposure can compromise battery performance, longevity, and safety. A prototype manufacturing laboratory in Latvia required a specialized dehumidification system to maintain ultra-low humidity levels at 15ºC—equivalent to a dew point of -45ºC or lower.

Standard desiccant dehumidifiers can remove deep levels of moisture but are limited by humidity content in the regeneration air. The challenge was to achieve extremely dry conditions without external contamination, ensuring a stable environment for high-precision battery assembly.

The Solution

Innovative Closed-Loop Desiccant Dehumidification System

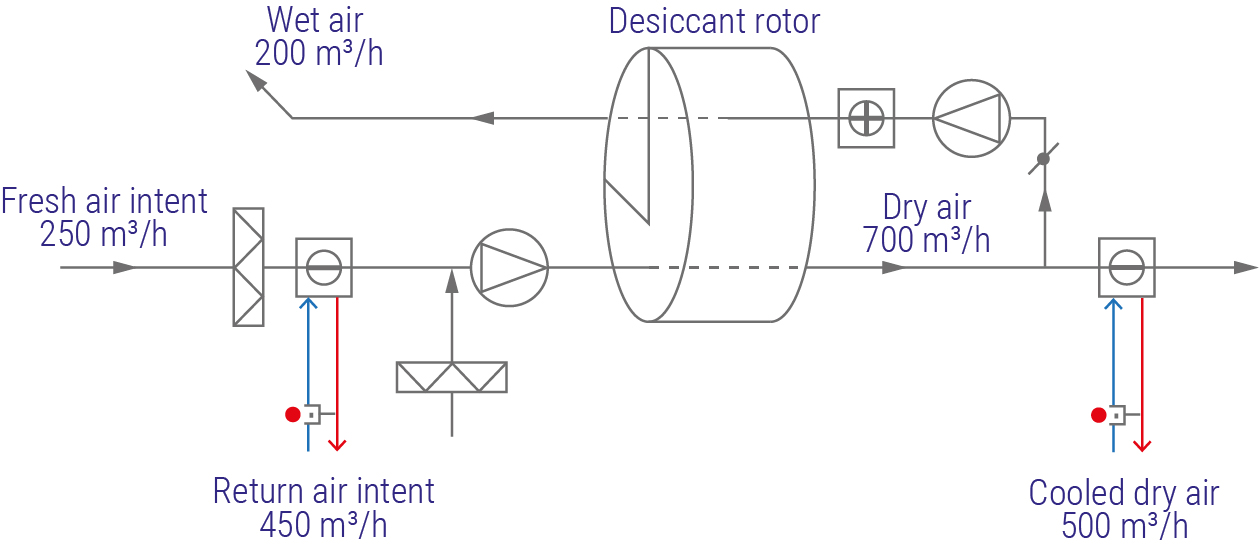

DT Group engineers developed a customized dehumidification layout, incorporating a closed-loop air drying process that dramatically enhances moisture removal.

- Air Recirculation for Maximum Efficiency – Instead of drawing in ambient air, the system reuses already dehumidified air, significantly increasing drying capacity.

- Ultra-Low Humidity Control – Achieved a humidity content of just 0.1 g/kg at 15ºC, providing a stable microclimate for sensitive Li-ion battery materials.

- Integrated Cooling & Humidity Control – Fresh air intake is pre-cooled to condense excess moisture, then mixed with return air before entering the desiccant rotor for further drying.

Fully Autonomous Operation – The unit automatically regulates airflow, humidity, and temperature, ensuring consistent performance.

Key Features of the MDC DRYROOM System

- Prevents moisture damage to highly sensitive Li-ion battery prototypes.

- Maintains ultra-low dew points required for high-precision manufacturing.

- Integrated pre- and post-cooling system for enhanced air treatment.

- Uses dry air for regeneration, maximizing energy efficiency.

The Results

Reliable, High-Performance Humidity Control for Battery Manufacturing

The MDC DRYROOM installation, with a capacity of 500 m³/h, fully controls the humidity conditions in a 30 m³ prototype laboratory, providing:

- Consistent ultra-low humidity for Li-ion battery production.

- Protection against contamination, improving product quality and safety.

- Optimized energy efficiency through air recirculation and cooling integration.

By leveraging advanced desiccant dehumidification, DT Group has helped the Latvian laboratory achieve the extreme humidity control required for next-generation Li-ion battery innovation.