Pharmaceutical Manufacturing Facility Climate Control

Project: DA-15000

Quick Scrolls

The Challenge

Precision Climate Control in Pharmaceutical Manufacturing

Pharmaceutical production demands strict environmental controls to maintain the quality, safety, and efficacy of medications. Key factors include:

- Precise humidity regulation to prevent ingredient degradation and contamination.

- Consistent temperature control to ensure stable production conditions.

- High air purity standards to comply with pharmaceutical-grade cleanliness regulations.

Traditionally, separate systems handle these aspects – one for ventilation, another for dehumidification, and another for filtration. However, this approach is costly, space-intensive, and energy-consuming. Pharmacare PLC, a leading manufacturer in Ramallah, Palestine, required a single integrated solution that could efficiently manage all these requirements.

The Solution

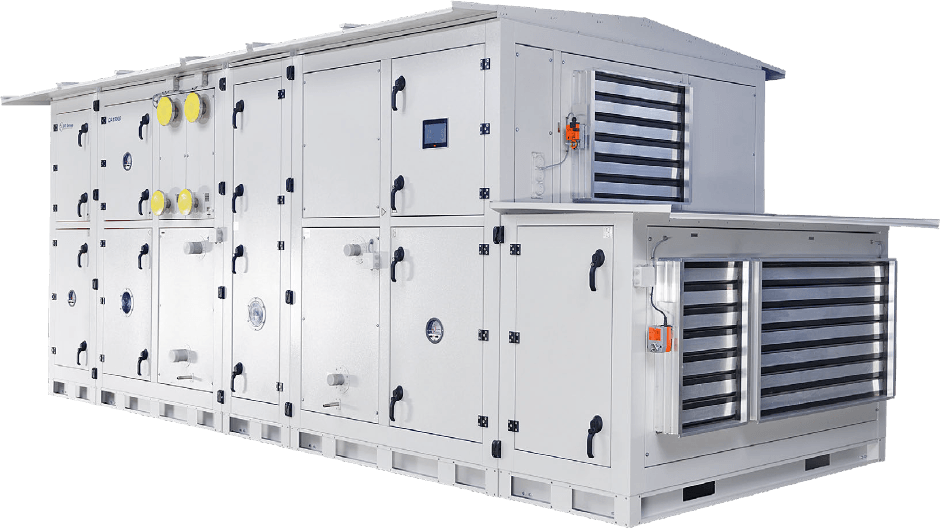

A Multi-Function Air Handling & Dehumidification System

DT Group engineers designed and installed the DA-15000 air handling unit, a custom-built dehumidification and ventilation system that combines:

- Precise Humidity & Temperature Control – Maintains 11ºC air temperature at 1 g/kg absolute humidity, preventing moisture-related product degradation.

- Advanced Air Purification – Integrated HEPA H13 filtration ensures a sterile production environment, eliminating airborne contaminants.

- Weatherproof & Durable Design – UV-resistant casing and special roofing protection allow for reliable outdoor installation.

- Automated Monitoring & Remote Access – A touchscreen control panel with Ethernet support enables real-time system monitoring and remote adjustments from any internet-connected device.

- Efficient Airflow Management – A 14,000 m³/h nominal airflow capacity optimizes air distribution throughout the facility.

Key Features of the DA-15000 System

- All-in-One Air Handling & Dehumidification Unit (combining ventilation, drying, and purification).

- Precise climate regulation tailored to pharmaceutical industry requirements.

- Integrated HEPA H13 filtration for high-purity air supply.

- Web-based monitoring and remote control for real-time adjustments.

- Weatherproof construction for outdoor installation, ensuring longevity and resilience.

The Results

Enhanced Efficiency & Compliance in Pharmaceutical Production

With DT Group’s DA-15000 system, Pharmacare PLC now benefits from:

- A fully controlled production environment, ensuring compliance with pharmaceutical-grade standards.

- Increased operational efficiency, with lower energy consumption compared to multiple standalone systems.

- Remote monitoring capabilities, allowing proactive maintenance and real-time adjustments.

By integrating dehumidification, air purification, and climate control into one advanced system, DT Group has helped Pharmacare PLC streamline operations and maintain strict production conditions with maximum efficiency and reliability.