Desiccant Dehumidifiers: MDC Range

MDC12000

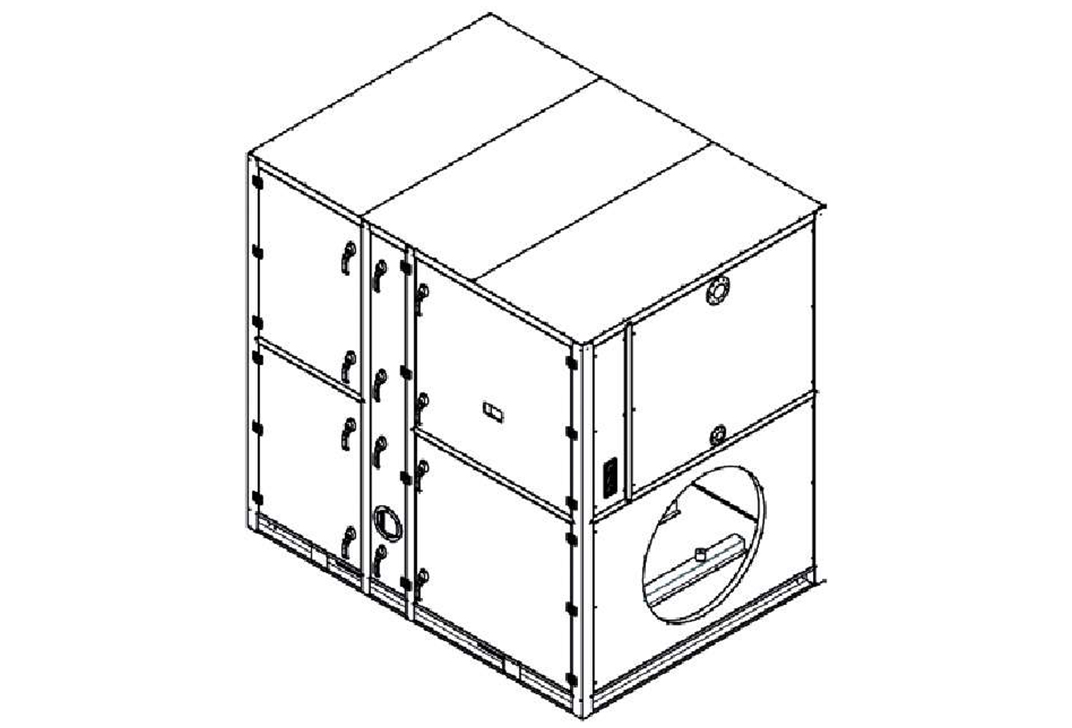

Desiccant dehumidifier MDC12000 designed for general purposes – room air dehumidification and process drying. The compact construction allows extended periods of operation with a minimum of maintenance. Especially suitable for low temperature and low humidity operation. Unit includes desiccant rotor, ECfans, reactivation heater, pocket filters and controls. Panels insulated with 40 mm rock wool insulation.

Rated airflow – 12000 m³/h

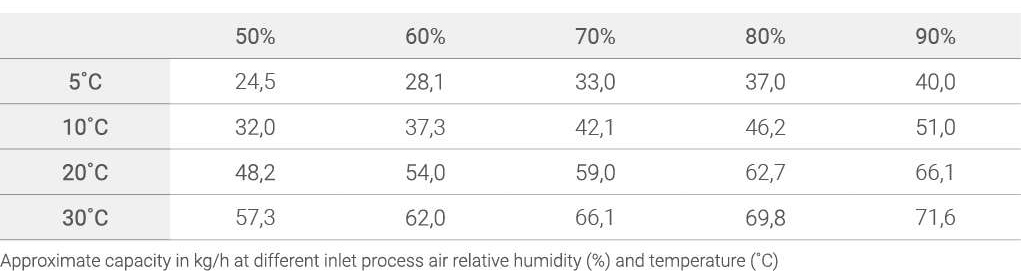

Dehumidification – 85 kg/h (20ºC/60% RH)

Power supply – 144 kW (3х400V, 50 Hz)

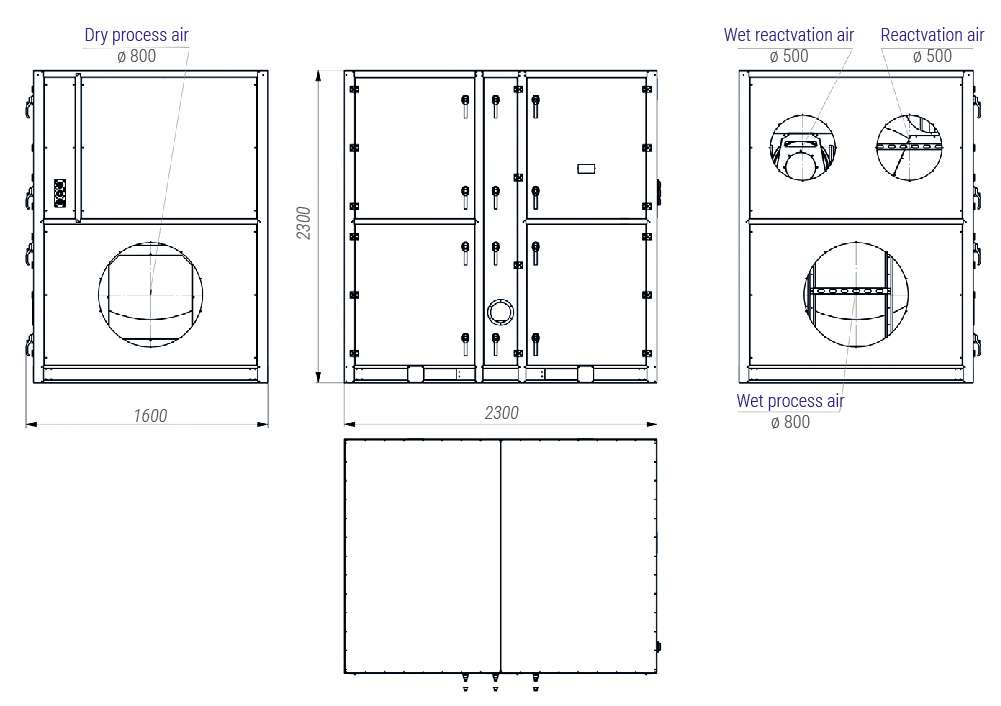

Dimensions – 2300x1600x2300mm

Construction Features

- The casing is completely hermetic and panels are made of 1,0mm AluZinc sheet metal with isolation of

40mm (rock wool); it has high resistance to atmospheric corrosion. Powder painted panels (outside only);

rigid frame made of 1,5mm AluZinc sheet metal (powder painted completely) to achieve rigidity; - Compact design and low weight of the unit;

- High performance at low temperatures and low relative humidity in a room;

- Optional humidistat is available as an accessory;

- Microprocessor based control (optional);

- Tubular electric heating elements for regeneration (standard unit) as well as on request with water, steam or

gas heating coil (customized unit); - Easy access to the internal components of the dehumidifier for the maintenance;

- EC-fans;

- Pocket filters G4 to F9 on request;

- High efficiency of the washable silica gel rotor;

- All components made exclusively by European manufacturers.

Technical Data

Process air

Rated airflow – 12000 m³/h

Available static pressure 550 Pa

Reactivation air

Rated airflow 4200 m³/h

Available static pressure 400 Pa

Power supply (electric reactivation)

(3х400V, 50 Hz) 144 kW

Current 210 A

Power supply (steam/water/gas reactivation)

(3х400V, 50 Hz) 12 kW

Current 18 A

Miscellaneous data

Weight 1400 kg

Operating temperature -30/+40˚С

Max noise level without ductworks 73 dBA

Air filter (pocket) G4÷F9

IEC protective class IP55

Insulation 40mm